It can be used to engrave, cut, and etch iron, steel, aluminum of up to 20mm thickness.

#Laserdrw k40 professional

Therefore, professional training is required before you can operate fiber laser-based devices.įiber laser is suitable for metals and non-metallic materials alike. However, the fiber laser produces bright light in the visible spectrum that can damage eyesight. However, manufacturers avoid using a fiber laser in their devices due to its high cost and powerful applications. These lasers are far more powerful than any other and can melt pretty much any material and thickness.

For instance, the wavelength produced by the fiber laser can reach up to 1064 micrometers.

#Laserdrw k40 series

Instead of reflective glass, it uses a series of fiberglass tubes to reflect and amplify the laser’s intensity by up to several hundred times. Fiber Laser:įiber laser is the most powerful type of laser used in engraving devices.

However, the laser used in most engravers uses 25-100W to provide a wavelength of 10.6 micrometers. Power:ĬO2 lasers can provide a power of up to several Kilowatts. Some people even melt food items with CO2 laser, including cheese, plants, chestnuts, and butter. The CO2 laser is suitable for engraving on wood, paper, plexiglass, non-ferrous metals like aluminum and acrylic materials. Moreover, the laser produced by CO2 is in the invisible light spectrum and doesn’t damage your eyes. These high-speed atoms are then focused on the material through a series of mirrored lenses with maximum reflective index. When high-voltage electric current passes through the cloud, the gases ionize to form cations and anions. The gas tube inside the laser contains a cloud of carbon dioxide, some inert gas like helium, and few other gases. It is because CO2 lasers are safer than others, and they can cut a wide range of materials. CO2 Laser:ĬO2 is probably the most commonly used laser engraver for small businesses and home DIY projects. Therefore, you need to understand the type of material that you are working with before choosing the best laser cutter and engraver. Each type of laser is suitable for vaporizing the different materials and specified thicknesses. However, there are three types of laser cutters depending on the type of laser used in the device. Laser cutters are based on the latest technology that provides a convenient way to engrave and etch several materials without any physical exhaustion. In short, laser engraving is the most accurate and efficient way to engrave any design on several materials.

#Laserdrw k40 software

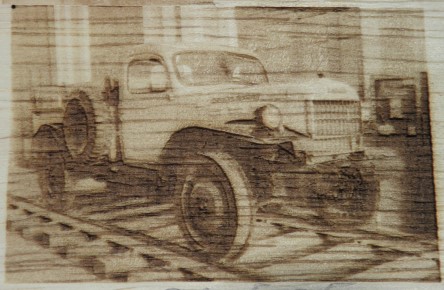

The laser cutter is connected to computer software that controls the laser’s movement and intensity according to the vector image provided. The vaporized portion of the material leaves behind permanent markings of up to a few mm thickness. This scientific fact was recently proven experimentally by the YouTuber, TheActionLab. Even combustibles like wood and fabric have a certain melting point at which they start vaporizing. Did you know?Įvery material found on earth has a specific melting point. When the laser comes in contact with the material under consideration, it starts vaporizing it. The ions are focused on the material in the form of a laser by means of several powerful lenses. The powerful ionizer of the laser engraver ionizes different gases in the laser to produce anions. On the contrary, advanced laser engraving technology uses a powerful laser beam to penetrate the material’s surface and engrave digital designs automatically with an accuracy of 0.001mm.

#Laserdrw k40 crack

However, the method was not efficient enough as there is no room for mistakes, and the impact force could damage or crack the material. In those days, design, patterns, and texts were engraved on slabs of wood and rock by etching. Material engraving is an ancient art first used by the Chinese, and then it found its way to ancient Egypt. To etch various materials according to your desired shape, you can double the laser engraver as a 3D laser cutter. A laser engraver is a powerful machine that focuses high-speed CO2 laser beams through an optical path system to cut, etch and engrave solid materials.

0 kommentar(er)

0 kommentar(er)